Let us make a bet... I am certain you are reading this article by using an electronic device, and if not… well tell me how and I’m sure we could be millionaires in a blink of an eye.

I also know that the world we are living in has been having a lot of changes, in fact, due to the pandemic, we all have had a “big change” which resulted in a higher dependence on technology. Just imagine, or I may say remember, in a period of less than three months we were all in lockdown, and thankfully most of us had the opportunity of working or studying from home. But that also meant having to turn on that old dusty computer we barely used when our main device broke or, in other cases, it meant getting some device to adapt to the situation.

However, while all this change is happening there is one thing we may not be having in mind, and it started long before the pandemic. Let me give you a hint:

Do you know what these devices have in common?

Let me widen the scope by adding few other devices:

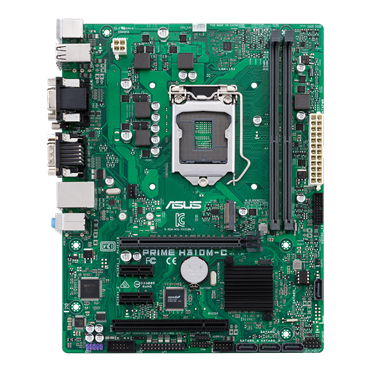

I believe that so far you got the idea. What all these devices have in common is related to this big green part… a circuit board.

Ok, now you may think, what is the matter with it? We have been using those since the Fifties. Why should we care about it now?

Yeah, but since then we are having a higher need for these devices, not only because of the pandemic, but before due to advances in technology. Nowadays devices are changed in a short time span. Almost everyone has purchased more than three devices in the last two years. This is directly related to the device’s useful life, since the average lifespan of a laptop is two to three years and for a mobile phone is fifteen to eighteen months. This results in an exponential consumption of devices which leads to a big ecological problem. “The e-waste”.

How do we handle that problem?

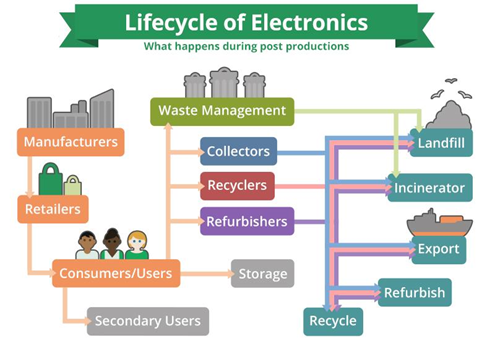

We kind of have four options:

● Store them at home.

● Throw them in the trash can.

● Reuse them.

● Recycle them.

I believe by now you already know the option I am going to focus on. Recycling e-waste.

There are many processes, technologies and companies involved in the recycling process. But all of them have one goal, get those precious materials that can be reused, repurposed, and sold.

What materials?

The ones we can see easily on circuit boards are the metals, on the components or within the board. Just from that component we can get tin, copper, palladium, and gold. Besides metals we can get plastics, and, in some cases, we can get glass.

The process

Recycling is a complex process, but we can summarize the whole process into three simple steps:

- Collection and Transportation

This consists of gathering the disposed electronic devices as monitors, keyboards, mouses, pc, laptops, and so on. If it has some sort of circuitry, it can be used.

All of those gathered devices are transported to the recycling centers for them to be processed.

- Sorting, Shredding, and Separation

The sorting process is an important part, because since we have different types of electronic devices, they have different components. Some of them have hazardous or special materials that require different recycling processes like batteries or glass.

After the materials have been sorted, they start the crushing and shredding process. This part consists in breaking apart the materials as little kids with new toys. In the industry this process is handled by a shredder granulator or centrifugal shredders and these do a way better job than little kids.

The centrifugal shredders got my special attention because they take the material and start spinning it until it breaks, usually within a chamber to avoid pieces being thrown everywhere.

When the shredding is done, the separation process starts, which can be kind of tedious. There are several processes to separate materials we have magnetic removal, metallic and nonmetallic separation that can be done with water or air (on both cases plastic would be separated because it would be pushed by compressed air or it will float on the water), separation of metals using Eddy currents, and the laser beam separation in which we get different materials in a solution or cloud of dust.

One of the separation methods that got my attention was one from a company in New Zealand that uses this specific species of bacteria and fungi that evolve to bond with specific metals (like gold or palladium). The process consists in mixing the shredded material with the bacteria and fungi, usually using a batch mixer until you get a paste. That paste is then dried with a batch dryer until no water is left on the paste. The resulting material is then burned until only the metal is left to be refined into the desired product.

As I have been saying, there are a lot of systems involved, and a lot of ways to do so, my favorite being the shredding of course. But all of these would not make sense if it were not profitable. That is how we link the last step.

Preparation For Sale as Recycled Materials

The preparation is somewhat simple after the process is done. The goal is that all the resulting materials are exported and sold as recycled materials (as plastic and metals). Sometimes there is remaining material that goes to incinerators or, in some cases, to landfills (usually this is avoided since it is the main purpose of the recycle centers).

As you can see the e-waste recycling process uses many different systems. Luckily here at Triangular we have access to most, if not all, of those systems. Do not forget to contact us and find out more about our new platform.