By Elmar Bartsch (CFO, Triangular), 29/01/2021

It is found everywhere where lightness is supposed to meet strength. The C stands for the chemical element carbon. It is not radioactive and it is in a solid state at room temperature. It describes the C in CFRP, a very special composite material. With an atomic mass of 12.011 u, it forms the molecular basis for all life on earth. It is available everywhere and at the same time precious and rare when it appears in its purest form, the diamond.

The C is versatile and capable of forming complex molecules. It is the champion among the elements. No other element can make more connections. The Latin word "carbo", known worldwide as charcoal, gives its name to the famous high-tech material carbon. Especially in lightweight construction, this composite material has earned a very good reputation and seems indispensable when it comes to performance. However, the term carbon still needs to be clarified. Because we are actually talking about CFRP, a carbon-fibre-reinforced plastic.

The monocoque of an Formular 1 car is largely made of it and nowadays many important components in aircraft construction would be inconceivable without CFRP. In model construction CFRP parts like spars, tubes, propellers, rims, support frames, and others are also often used to improve model characteristics. Further prominent examples from everyday life are fishing rods, racing bikes or medical protheses.

In industry, the high-tech material CFRP has become an integral part of product design. It consists of carbon fibres and plastics. That are the components which have a decisive influence on the material properties. Each component contains the magic C, carbon. The task of the process industry is to supply the raw materials to produce CFRP. Crushing, grinding, drying, micronizing, classifying or mixing - when it comes to the production of solid or liquid precursors, Triangular can help find the right equipment or material experts in the mineral or chemical industry.

Let us first take a look at carbon fibres, the CF in CFRP. The central process for transforming organic fibre into carbon fibre is pyrolysis. In this processing step, the carbon content of the fibre is increased to over 90%. During this process, the fibre is exposed to different pressures and temperatures between 1,200°C and 1.800°C. The process is very energy intensive. After the final high-temperature treatment, the finished carbon fibres are wound in bundles (named rovings) onto a spool and then further processed into a flat carbon tissue. The starting material for carbon fibre production is often the synthetic material PAN. The abbreviation stands for polyacrylonitrite. When the material is not being carbonised, it is used in well-known textile products such as knitwear, blankets, curtains or carpets.

The pure carbon tissue is, like a jumper, easily deformable and soft. Only together are they strong! In order for the outstanding properties of CFRP to come about, the RP of CFRP is also needed. It stands for plastic, or more precisely resin and hardener. An epoxy resin is usually used in the production process. This resin adheres best to the carbon fibres and is thermosetting after curing, which means it can no longer be deformed by heat. Only when the carbon fibres are immovably embedded in the cured resin do the material properties for which CFRP is famous emerge: light, break-resistant, tensile, heat-resistant and at the same time up to 80% lighter than steel.

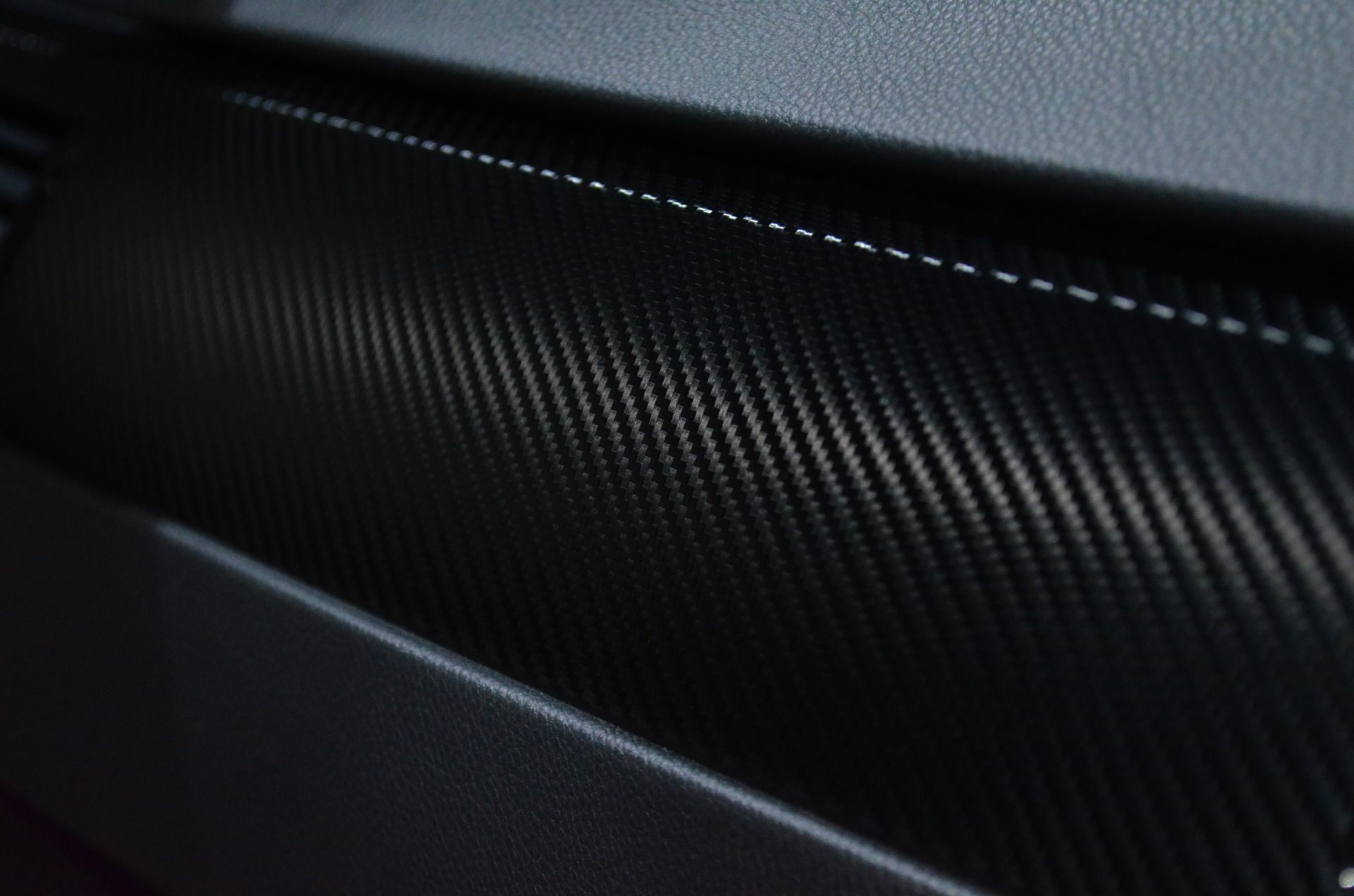

In the production of CFRP, it is also of central importance to pay attention to the direction of the fibres. Only in the direction of the fibres is the material stable and resistant to tensile forces. This also explains the well-known appearance of carbon components. In order to obtain strength in all directions, the carbon fibres have to be laid in different directions during production, which we then perceive as complex connection patterns, often meshes of diamonds or squares.

As a model maker, I appreciate not only the material properties but also the fact that the finished CFRP material can be processed relatively easily. Drilling, milling, turning or grinding are available as well as gluing. If the CFRP is to be visibly installed, then polishing or larnishing can be considered for the finish. The result then not only looks high-tech, it is high-tech.