May.

A look out of the window. This May is moody like an April. On a sunny day, we play in the park. The other day, I see snow flakes on the car and I have an appointment to change the tyres at 9am. Perfect timing?

2 hours later I have a bill to settle: 4x new summer tyres, wheel change, tyre disposal.

Since than I see scrap tyres everywhere. In the park, in the neigbours garden, in the local press....

- What happens to the tyres I left at the car service?

- Is there an "afterlife" for our tyres?

- What exactly is made of them?

- How does the process looks like?

- Is the process sustainable?

Some facts to start our journey

- 13.5 million tons are dismounted each year worldwide

- 4.4 million tons in US

- 3.4 million tons in Europe

- 49.4 million car tyres were produced 2019 in Germany

- 650 000 tons old tyres are disposed

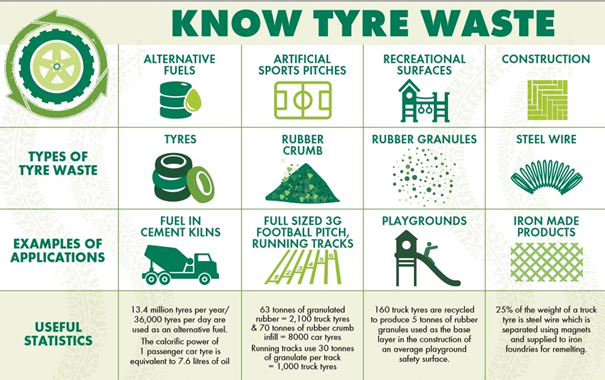

- 52% of scrap tires are burned for fuel in e. g. cement manufacturing

- 12% are used in crumb rubber products

- 16% are used for civil engineering applications

- at least 14% are ground and dumped in landfills

- 7 Million Dead Tires lies in the World’s Largest Rubber Graveyard in Kuwait (visible from space)

The statistics differ from country to country.

During my research I found a lot of recent articles in European press about fire on tyre landfills. The black smoke was scary. The pictures shocked me.

Scrap tyres seems to be a challenging source of waste, due to the large volume produced, the durability of the tyres, and the components in the tyre that are ecologically problematic. Because tyres are highly durable and non-biodegradable, they can consume valued space in landfills. The illegal landfill or “tyre waste crime” is still a big issue. Why?

Tyres provide valuable resources!!!

By transforming used tyres into a useful commodity, carbon emission is reduced.

Just to mention few alternatives:

- Tyres can be used as fuel for cement manufacturing

- Repurposing and art are kind of “second use” (I am completely convinced that the modern recycling methods serve our climate and economy in more sustainable way).

- Rubber granules are used for running tracks, fall protection surfaces, ant-slip mats, artificial turf, boundaries etc.

- Recovery of CARBON BLACK

Let us explore the recovery of Carbon Black closer.

In the last year at Triangular, I have been dealing with companies that either make systems that are used in tyre recycling or use Carbon Black (CB) or Recovered Carbon Blac (rCB) to create other products.

How does the recycling process work?

There are 3 common processes:

- Pyrolysis

- Devulcanization

- Micro-granulation

The simplified description for PYROLISIS which seems to provide most economical results for tyre recycling nowadays, would look like this:

- Scrap tyres (Feedstock) are going to be shredded into small pieces.

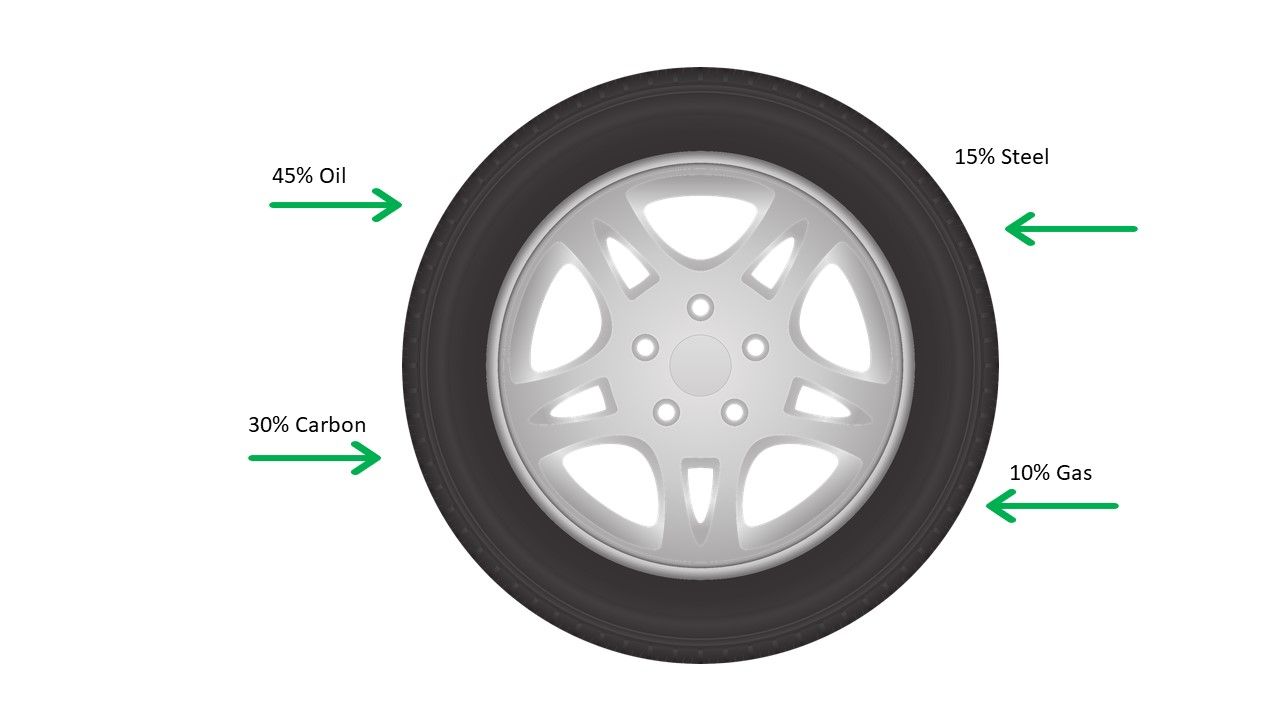

- In the REACTOR the feed material is processed with heat to separate GAS, OIL, CARBON and STEEL. This is the main part called PYROLISIS

- The size of the particles needs to be reduced further. They are pulverized in a MILL

- Finally, the fine powder is agglomerated in a PELLETISER & DRYER

What can be done with all recovered resources?

- Gas provides energy

- Oil is used to manufacture plastics, & other chemical products

- Steel is used as ore residue

- Carbon is used for plastics, pigments, new tyres* production

*On the one hand the prices for new Carbon black (CB) increase constantly and there is a shortage of these material. On the other hand, improving and stable quality for recovered Carbon Black (rCB) boost interest for this material. rCB has meanwhile very good properties (viscosity, hardness, strength…) and more and more tyre manufactures apply it in the production of new tyres.

Main challenges observed

- produced amount of rCB does not cover the need of the industry

- the quality of rCB varies and often do not fullfill the industry requirements

- systems and equipment are missing to cover the whole recycling process

- the investors are uncertain about the sector

- scrap tyres are seen as a problematic waste in many countries, as they have no access to the right technology and know-how

- illegal tyre landfills and fires are reported almost daily from all over the world

Recycling of tyres has improved in the last decade. It is profitable, sustainable and complete tyres can be recycled. For me this is a real innovation and step towards reduction of CO2 emission.

Further the Pyrolysis capacities have increased all over the Europe. The companies form they forums and discuss intensivly the chances, challenges and opportunities to grow the sector.

The number of opportunities to use tyre-derived materials is growing and creating new businesses as well as jobs. The market attracts many companies searching for sustainable solutions, sustainable materials and circular economy.

The huge investments of big chemical players in rCB projects confirm the trend.

I would love to discuss with you further on the trends in the recycling industry.

- Is investment in new recycling methods THE way to reduce tyre waste?

- Have you noticed a significant acceptance increase for rCB over the last 5 years?

- What are the main challenges that the tyre recycling industry is facing?

If you are interested to find out more about the recycling process, pyrolisis and CB here are some usufull links: